| View previous topic :: View next topic |

| Author |

Message |

prinmancz52

Regular Member

Joined: 04 Nov 2018

Posts: 27

Location: Tacoma, WA

|

Posted: Sat Sep 04, 2021 10:20 am Post subject: Tuning Slide Issue Posted: Sat Sep 04, 2021 10:20 am Post subject: Tuning Slide Issue |

|

|

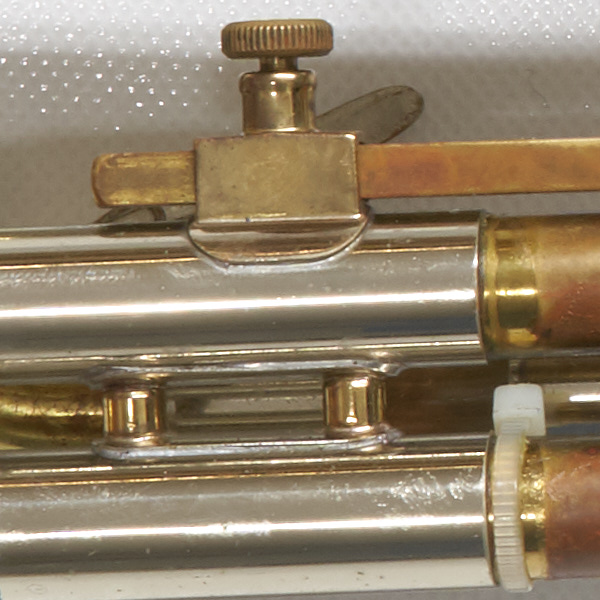

How to keep loose trumpet tuning slide from pushing in when emptying spit valve?

Is there perhaps a device to keep it in the position at which you are in tune?

Looking for something to hold the slide out about 1/4 inch. Right now, every time I empty spit valve, the slide goes back in!

Thanks!

_________________

Chuck

King Super 20 Silver Sonic Symphony (1965)

Reynolds Silver Bell and Lead-pipe 1938 Cornet |

|

| Back to top |

|

|

deleted_user_687c31b

New Member

Joined: 03 Apr 1996

Posts: 0

|

Posted: Sat Sep 04, 2021 11:49 am Post subject: Posted: Sat Sep 04, 2021 11:49 am Post subject: |

|

|

Well, the cheap options I can think of is either some DIY slide stop (using metal wire or maybe a 3d printed one) or maybe some thicker, less slippery slide grease (make sure to throughly remove the old grease before applying the new, or it might stay slippery).

Other things that might work is bending the tube ever so slightly (but get a tech to do it, don't do it yourself and ask said tech whether it's a good idea to begin with) or maybe have a tech add a slidestop (or even a pitch finder). That may affect the horn though.

Or maybe just remember the position it's in, and reset it there after emptying (that works on my french horn, which has no spit valves). |

|

| Back to top |

|

|

huntman10

Heavyweight Member

Joined: 30 Aug 2017

Posts: 681

Location: Texas South Plains

|

Posted: Sat Sep 04, 2021 12:28 pm Post subject: Posted: Sat Sep 04, 2021 12:28 pm Post subject: |

|

|

I had a Strad with LSS (loose slide syndrome). I got a device that you can insert into the inner slide tube and it expands and stretches the tube so it fits tighter. No slide slippage.... but it takes both hands to move the slide, now!  I just got a bit rushed and overdid it. I just got a bit rushed and overdid it.

And I did it to both my Bb and C Strads.

So I will say it is fixable, but find a reliable repairman to do it. I can take mine to my favorite shop and he has a set of dies to press over the tubes to press them down again, but so far, I can live with it as long as I keep the slides well lubed and leave the out if I am not using that horn regularly.

_________________

huntman10

Collector/Player of Fine (and not so fine) Brass Instruments including

Various Strads, Yammies, Al Hirt Courtois, Schilkes,

Selmer 25, Getzen Eternas, Kanstuls (920 Pic, CG)

Martin Custom Large Bore, Lots Olds!, Conns, etc. |

|

| Back to top |

|

|

zaferis

Heavyweight Member

Joined: 03 Nov 2011

Posts: 2317

Location: Beavercreek, OH

|

Posted: Sat Sep 04, 2021 12:49 pm Post subject: Posted: Sat Sep 04, 2021 12:49 pm Post subject: |

|

|

1. Live with it

2. Heavier/Stickier slide grease

3. Repair Tech.... get it fixed right.

my vote is #3

_________________

Freelance Performer/Educator

Adjunct Professor

Bach Trumpet Endorsing Artist

Retired Air Force Bandsman |

|

| Back to top |

|

|

ayryq

Veteran Member

Joined: 16 Feb 2019

Posts: 354

Location: Rochester, NY

|

Posted: Sat Sep 04, 2021 2:12 pm Post subject: Posted: Sat Sep 04, 2021 2:12 pm Post subject: |

|

|

Put your thumb opposite the spit valve lever so the slide doesn't move?

_________________

Yamaha YTR6345HGS Bb

Bach "Philly" C

Bach 239 Eb/D

DEG Signature 2000 Bb/A picc

Yamaha YTR-9835 Bb/A picc

Yamaha Bobby Shew flugel

Yamaha Neo cornet

|

|

| Back to top |

|

|

ebolton

Veteran Member

Joined: 03 Feb 2021

Posts: 123

Location: New Hampshire, USA

|

Posted: Sat Sep 04, 2021 4:42 pm Post subject: Posted: Sat Sep 04, 2021 4:42 pm Post subject: |

|

|

It depends on how much metal working you feel comfortable doing on a valuable instrument. There are several ways to tighten it up without making it immobile. Most people are probably best off using heavier grease.

Any grease will work. It doesn't have to be specific to musical instruments. I use Parker High Vacuum Silicone Grease on the slides that don't have to move much because 1) I have a tube; and 2) it works well and lasts a long time.

_________________

-Ed |

|

| Back to top |

|

|

Dayton

Heavyweight Member

Joined: 24 Mar 2013

Posts: 2025

Location: USA

|

Posted: Sat Sep 04, 2021 6:47 pm Post subject: Posted: Sat Sep 04, 2021 6:47 pm Post subject: |

|

|

| Take the horn to your local repair tech. It is typically a quick and inexpensive repair. |

|

| Back to top |

|

|

Brad361

Heavyweight Member

Joined: 16 Dec 2007

Posts: 7080

Location: Houston, TX.

|

Posted: Mon Sep 06, 2021 12:18 pm Post subject: Posted: Mon Sep 06, 2021 12:18 pm Post subject: |

|

|

Tech, or thick grease and live with it. But if the slide moves that easily, there’s a good chance that it’s also leaking slightly.

That being said, my understanding is that the absolutely correct fix is to replace the tubes (that are attached to the crook), and have it lapped/fitted as a new slide. Expanding the tubes (again, TECH!) works too, but you’re actually SLIGHTLY changing the tube diameter by doing that. Will that be noticeable? Maybe, maybe not, everything affects something.

Back in prehistoric times, we would usually just bend the tubes a bit, but that’s pretty much universally understood as not being a good way to go; messes up alignment and fit. Hey, what did we know, we thought polyester leisure suits and platform shoes looked good.😉

Brad

_________________

When asked if he always sounds great:

"I always try, but not always, because the horn is merciless, unpredictable and traitorous." - Arturo Sandoval |

|

| Back to top |

|

|

nieuwguyski

Heavyweight Member

Joined: 06 Feb 2002

Posts: 2343

Location: Santa Cruz County, CA

|

Posted: Mon Sep 06, 2021 5:58 pm Post subject: Posted: Mon Sep 06, 2021 5:58 pm Post subject: |

|

|

| ayryq wrote: | | Put your thumb opposite the spit valve lever so the slide doesn't move? |

+1, unless the OP can explain why it's not an option.

_________________

J. Notso Nieuwguyski |

|

| Back to top |

|

|

Brad361

Heavyweight Member

Joined: 16 Dec 2007

Posts: 7080

Location: Houston, TX.

|

Posted: Mon Sep 06, 2021 6:31 pm Post subject: Posted: Mon Sep 06, 2021 6:31 pm Post subject: |

|

|

| nieuwguyski wrote: | | ayryq wrote: | | Put your thumb opposite the spit valve lever so the slide doesn't move? |

+1, unless the OP can explain why it's not an option. |

Seems to me that if his slide is as loose as it sounds like it might be, it might be leaking slightly, and even moving on it’s own while being played (I’ve had two horns do that). So sure, a finger in the right place might stop it from moving when the spit valve is depressed, but that won’t address the other issues.

Brad

_________________

When asked if he always sounds great:

"I always try, but not always, because the horn is merciless, unpredictable and traitorous." - Arturo Sandoval |

|

| Back to top |

|

|

Trumpetingbynurture

Heavyweight Member

Joined: 18 Nov 2015

Posts: 898

|

Posted: Tue Sep 07, 2021 1:23 am Post subject: Posted: Tue Sep 07, 2021 1:23 am Post subject: |

|

|

Try Hetman's no. 7 Lubricant Gel.

If that doesn't work, get a repair tech to enlarge it slightly. |

|

| Back to top |

|

|

Andy Cooper

Heavyweight Member

Joined: 15 Nov 2001

Posts: 1825

Location: Terre Haute, IN USA

|

Posted: Tue Sep 07, 2021 9:15 am Post subject: Posted: Tue Sep 07, 2021 9:15 am Post subject: |

|

|

1. Ask your repair person if they can get replacement male tubing of the correct ID and OD. (It's probably ID .458) If they can, get a quote for replacement of the tubing on the tuning slide.

2. If the price is reasonable, have them expand the existing tubing - that's fast and cheap. Now you can make a decision.

3. If you do not like the playing results of the expanded tubing, then go for replacement of the male tube or tubing. Your King is a great trumpet worth the money to put in it's best playing condition.

Sure you could just bend the tubes out of alignment but that adds tension to the slide that you may notice.

(What a great excuse to upgrade your horn with a several hundred dollar custom solid silver crook tuning slide from M/K Bending and Drawing.) |

|

| Back to top |

|

|

Beyond16

Veteran Member

Joined: 07 Jan 2020

Posts: 220

Location: Texas Gulf Coast

|

Posted: Tue Sep 07, 2021 5:00 pm Post subject: Posted: Tue Sep 07, 2021 5:00 pm Post subject: |

|

|

What about a plastic cable tie?

It seems to me if a slide could be perfectly manufactured and aligned and corrosion free, then it has to be loose. Otherwise it becomes a 'press fit'. So I think we are stuck with keeping various grease types around. |

|

| Back to top |

|

|

|